Details

MKS AX7710SM-01 Remote Plasma Source

Product manual:

MKS AX7710SM-01 is a Remote Plasma Source (RPS) primarily used in semiconductor manufacturing

Flat panel display manufacturing and other high-precision industrial fields. The following are its main application areas and characteristics:

Main application areas

Semiconductor Manufacturing

Used for wafer cleaning, etching, and thin film deposition processes to remove photoresist and residues.

In advanced packaging technology, it is used for surface treatment and cleaning.

Flat panel display manufacturing

Used for cleaning and surface treatment in LCD and OLED panel manufacturing to improve display quality.

Used for etching and deposition processes in thin film transistor (TFT) manufacturing.

Manufacturing of solar cells

Used for silicon wafer cleaning and surface treatment to improve the efficiency of solar cells.

In the manufacturing of thin-film solar cells, it is used for etching and deposition processes.

Optical device manufacturing

Used for cleaning and surface treatment of optical components such as lenses and prisms to improve optical performance.

Research and Laboratory

Used for material surface modification, thin film deposition, and plasma research.

Product Features

Low damage: reduces damage to sensitive materials and is suitable for high-precision processes.

Flexible configuration: can adapt to multiple gases (such as O ₂, H ₂, N ₂, CF ₄, etc.) to meet different process requirements.

Easy to integrate: Modular design makes it easy to integrate into existing devices.

Low maintenance: The design is simple and the maintenance cost is low.

summarize

The MKS AX7710SM-01 remote plasma source, with its high efficiency, low damage, and high stability,

Widely used in fields such as semiconductors, flat panel displays, solar cells, etc., to help users improve process quality and production efficiency.

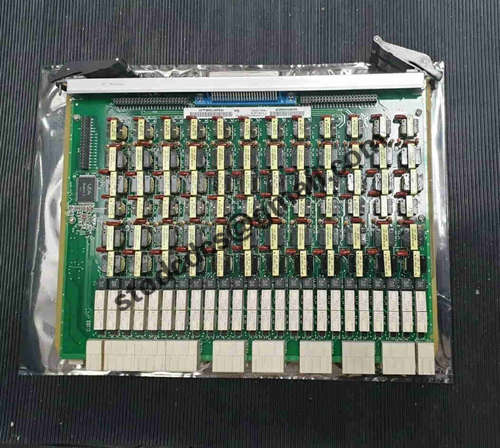

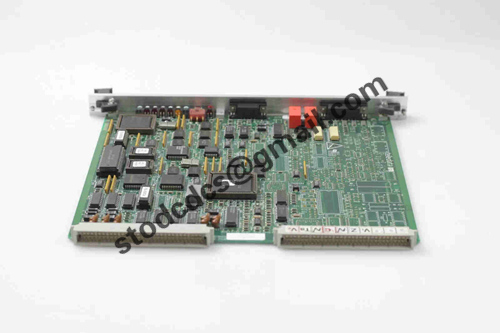

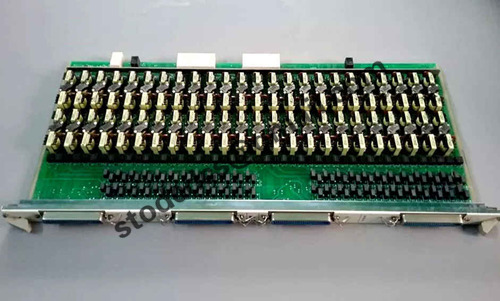

Product details picture:

More related products:

6ES7315-2AF03-0AB0processormodule

YOKOGAWANFAI841-S00Input/outputmodule

YAMATAKEEST0240Z05WBX00Touchscreen