Details

MKS AX7695PSK-10 Remote Plasma Source

Product manual:

MKS AX7695PSK-10 is a high-performance remote plasma source,

Widely used in surface treatment and cleaning processes in semiconductor, display panel, and solar cell manufacturing.

Main features:

Efficient plasma dissociation: capable of providing over 95% gas dissociation rate in the range of 1 to 10 Torr, improving process efficiency.

High flow processing capability: Supports gas flow rates up to 6.0 slm (standard liters per minute), suitable for high flow process requirements.

Integrated design: Built in quartz vacuum chamber and RF power supply, compact structure, easy to install directly on the process chamber.

Multi gas compatibility: capable of handling various gases such as O ₂, N ₂, H ₂, H ₂ O, etc., suitable for chemical vapor deposition (CVD), etching, de gluing and other processes.

Intelligent control: Supports simulation and EtherCAT communication, making it easy to integrate into automation control systems and achieve precise control.

Application areas:

Semiconductor manufacturing: used for high-density plasma treatment of wafer surfaces to improve the uniformity of etching and deposition processes.

Flat panel display production: used for cleaning and surface modification to improve display manufacturing yield.

Solar cell manufacturing: Enhance the surface treatment process of solar cells to improve the photoelectric conversion efficiency.

MKS AX7695PSK-10 has become one of the key plasma source equipment in modern high-end manufacturing industry due to its efficient and reliable performance.

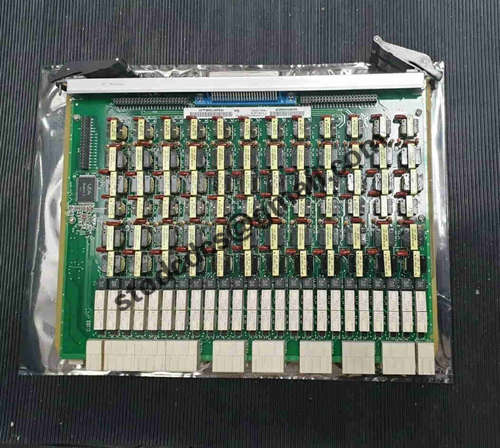

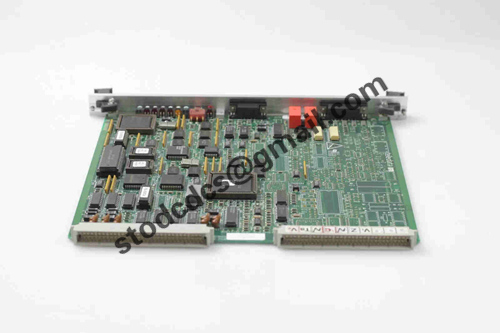

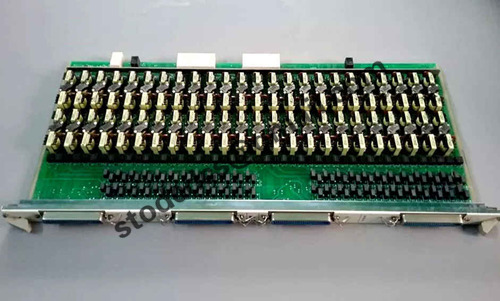

Product details picture:

More related products:

6ES7313-6BF03-0AB0Input/OutputModule