HARMONIC FHA-32C-100-E250-C Simulator Servo Motor

Brand:HARMONIC

Model FHA-32C-100-E250-C

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

HARMONIC FHA-32C-100-E250-C Simulator Servo Motor

Product manual:

Main features:

High torque density: With high torque output density, it provides powerful power in a compact design.

Low backlash: Adopting harmonic deceleration technology, it has a very low backlash to ensure smooth and precise motion control.

Simulator function: Typically used for simulating, testing, and verifying the performance of servo systems to ensure their reliability in practical applications.

High responsiveness: With fast response time, it can track and adjust the position and speed of the motor in real time to meet dynamic control requirements.

Encoder resolution: Equipped with a high-resolution encoder, providing accurate feedback information to optimize control accuracy.

Technical specification summary:

Model: HARMONIC FHA-32C-100-E250-C

Motor type: servo motor, suitable for high-precision motion control

Torque output: high torque density

Reduction ratio: usually including high reduction ratio

Encoder Resolution: High Resolution Encoder

Work environment: Suitable for industrial environments, with excellent durability

Interface: Supports standard electrical interfaces to connect with controllers and drivers

Application areas:

Industrial automation: used in automated production lines, robotic arms, and other industrial applications to provide high-precision motion control.

Robots: Used in industrial robot systems for high-precision motion and control, improving the flexibility and performance of robots.

Numerical Control Machine Tool: Used in numerical control machine tools to provide precise motor drive and support complex machining tasks.

Experiment and simulation: Used in laboratories and testing equipment to simulate and verify the performance of servo systems, ensuring the reliability of the system.

Usage suggestion:

Installation and Debugging: Install and debug correctly according to the product manual to ensure compatibility and performance between the motor and control system.

Control system configuration: Ensure compatibility between servo motors and controllers, correctly configure system parameters to optimize performance.

Maintenance and inspection: Regularly check the working status of the motor and maintain the system to ensure long-term stability and reliability of the system.

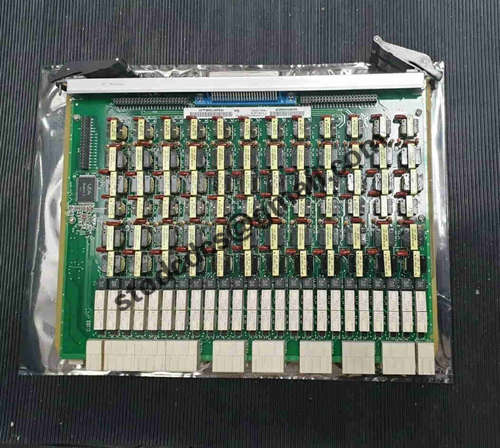

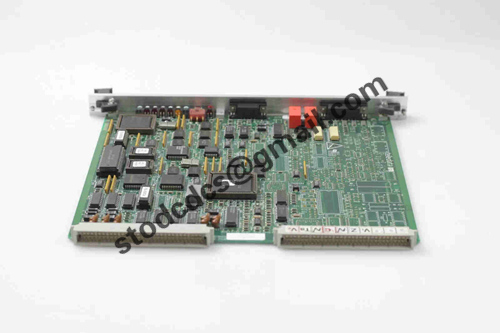

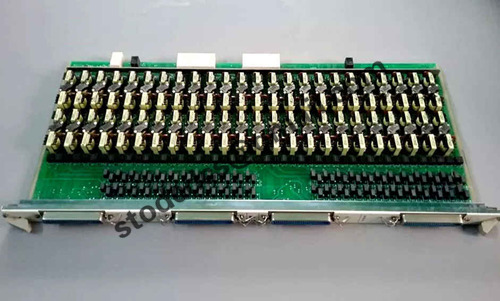

Product details picture:

More related products:

500BIO01 1MRB150005R1J inverter control unit

5SHX1445H0001 Low volta power supply chip