Details

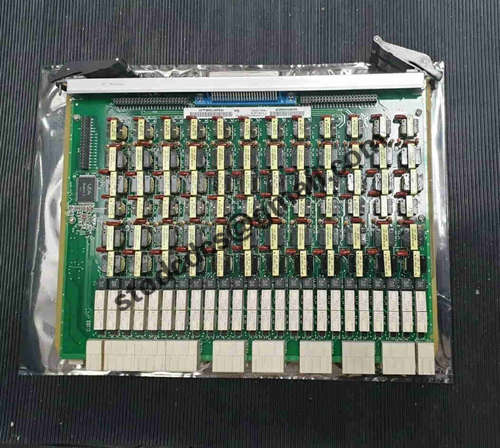

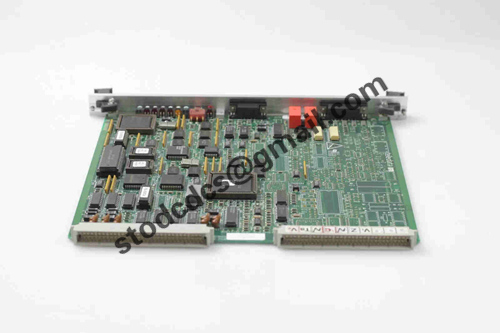

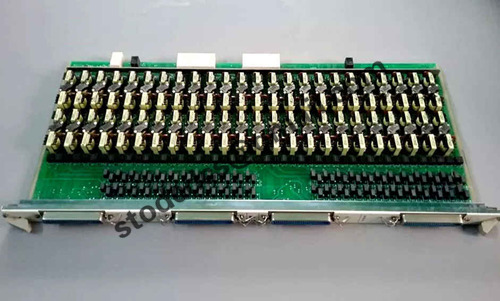

GE IS200AEPAH1AFD Turbine Control Module

Product manual:

Core functions:

Power distribution and management:

Receive external power input and distribute stable power to various modules of the system.

Provide voltage regulation and overload protection functions to ensure the stability and safety of power supply.

Signal conditioning and interface:

Process turbine sensor signals (such as temperature, pressure, speed, etc.) and transmit the data to the control system.

Has strong anti-interference ability, ensuring signal accuracy and real-time performance.

High reliability design:

Adopting industrial grade components, supporting long-term continuous operation, suitable for harsh environments.

Provide redundant design to avoid system downtime caused by a single point of failure.

Modular architecture:

Can be easily integrated into the GE Mark VI turbine control system.

Support hot swapping function, simplify system maintenance and replacement process, and reduce downtime.

Technical specifications:

model: IS200AEPAH1AFD

System compatibility: GE Mark VI turbine control system

Power management:

Input voltage: 24V DC

Stable output: multi-channel allocation

Signal interface: compatible with multiple sensor data inputs

Working temperature:- 40 ° C to+70 ° C

Humidity range: 5% to 95% (non condensing)

Installation method: Standard 19 inch rack installation

Redundancy support: Supports redundant power and signal channels

Application areas:

Gas turbine and steam turbine control:

Real time monitoring and control of key parameters such as turbine speed, temperature, pressure, etc.

Power generation industry:

Ensure efficient and stable operation of power generation equipment in power plants.

Oil and Natural Gas:

Provide status monitoring and protection for rotating machinery such as compressors and pumps.

Industrial Automation and Process Control:

Suitable for control and data acquisition systems of various heavy industrial equipment.

Product details picture:

More related products:

D20EME10BASE-Tdigitalquantitycontrolmodule