Details

FFVO142 3BSE223732R0001 Visual Inspection System

Product manual:

FFVO142 (model: 3BSE223732R0001) is a visual inspection system provided by ABB, specifically designed for industrial automation and quality control. Here are some key features and functions of the system:

Main characteristics

High resolution image capture:

Equipped with a high-resolution camera, it can capture subtle product defects, improving the accuracy and reliability of detection.

Powerful image processing capabilities:

Adopting advanced image processing algorithms, supporting real-time analysis and processing of image data, capable of quickly identifying defects and anomalies.

Flexible configuration:

The system supports multiple configuration options and can be customized according to different detection needs to adapt to different production environments.

Integrated design:

Seamless integration with other automation equipment and control systems (such as PLC, SCADA) simplifies system deployment and management.

User friendly interface:

Provide an intuitive user interface for easy setup and monitoring, reducing the need for training.

Data recording and analysis:

The system can automatically record detection data, support subsequent analysis and quality traceability, which helps to continuously improve the production process.

application area

Manufacturing industry: used for product quality control, such as detecting welding points, coating quality, etc.

Food and beverage: Ensure that products comply with hygiene standards and label accuracy during packaging and label testing.

Electronics industry: detecting defects and assembly accuracy of electronic components to improve product qualification rate.

Applicability

The FFVO142 visual inspection system is suitable for various production lines, especially performing well in environments that require high-precision inspection and quality assurance.

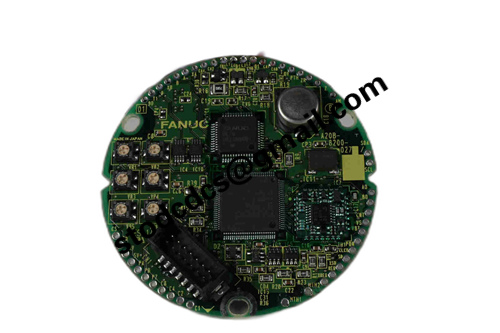

Product details picture:

More related products:

1MRK002133-ABr02 PC Ethernet adapter

3BHE039203R0101 Processor module