Brooks Automation 002-7391-25 Wafer Alignment Device

Brand:Brooks Automation

Model:002-7391-25

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

Brooks Automation 002-7391-25 Wafer Alignment Device

Product manual:

Brooks Automation's 002-7391-25 wafer aligner is a high-precision wafer positioning device,

Specially designed for precise alignment of wafers in semiconductor manufacturing processes.

This aligner can be fine tuned on multiple axes,

To ensure precise alignment of wafers during processing and testing, improving manufacturing accuracy and efficiency.

main features

Ensure that the wafer is always in precise position during handling and processing.

Multi axis adjustment: Supports multi axis adjustment function, including X, Y plane and rotation angle (Theta) adjustment,

Suitable for various complex alignment requirements.

Quick response and alignment: The design has optimized the alignment speed,

Capable of quickly completing wafer alignment operations, adapting to high-speed manufacturing processes, and reducing processing time.

Non contact alignment technology: using non-contact sensor technology,

Reduced damage to the wafer surface, particularly suitable for high-end wafer manufacturing that is sensitive to surfaces.

Stability and reliability: Durability and stability were considered in the design,

Capable of maintaining high-precision alignment for a long time, suitable for high load production environments.

application area

Semiconductor manufacturing: widely used in photolithography, etching

In processes such as ion implantation that require extremely high wafer positioning, ensure precise positioning of the wafer between different process steps.

Packaging and testing: During wafer level packaging and chip testing,

Aligners can ensure the position of each wafer or chip, helping to reduce testing errors and losses.

Other high-precision manufacturing: suitable for other precision manufacturing scenarios that require precise alignment,

Such as microelectromechanical systems (MEMS) and sensor manufacturing.

technical specifications

Alignment accuracy: sub micron level accuracy, meeting the requirements of high-precision wafer processing.

Non contact sensor type: supports multiple sensor options,

Used for detecting wafer edges and centers, achieving non-contact alignment.

Compatibility: Can be integrated into various automation equipment and manufacturing systems,

Support compatibility with mainstream semiconductor device communication protocols.

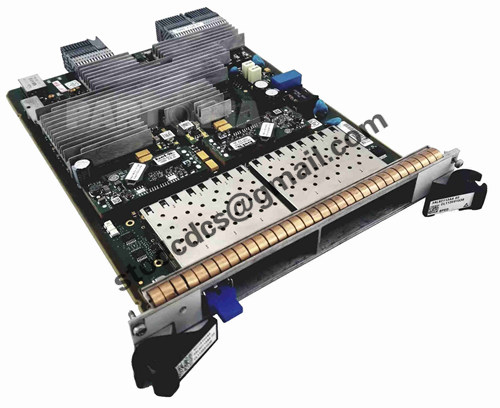

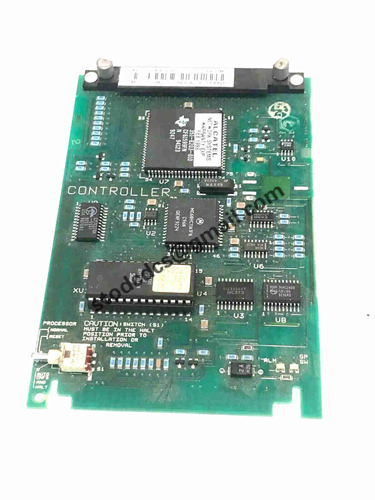

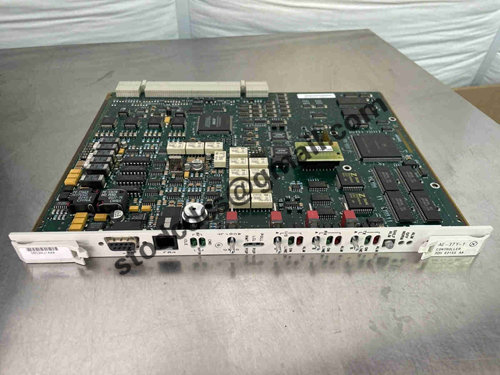

Product details picture:

More related products:

DSAI130A 3BSE018292R1 analog input board

DSPU131 3BSE000355R1 unit Interface board module