Brooks Automation 002-7391-07 Wafer Alignment Device

Brand:Brooks Automation

Model:002-7391-07

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

Brooks Automation 002-7391-07 Wafer Alignment Device

Product manual:

Application areas:

Mainly used in semiconductor manufacturing, integrated circuit (IC) packaging

Microelectronics and other precision manufacturing fields.

Usually used in wafer transfer lines as wafer loading

Unloading is an important component in other processing steps.

Capable of completing precise alignment tasks in automated production lines without the need for manual intervention.

Integrated vision system: Many wafer aligners are equipped with vision systems,

Capable of identifying wafer positioning, orientation, and other information through high-resolution cameras,

Assist in achieving precise positioning and alignment.

Performance characteristics:

High precision alignment: ensuring precise alignment of wafers during processing, inspection, or transportation,

Avoid production defects caused by inaccurate alignment.

High speed: Devices typically have fast operating speeds,

Enable the alignment process without manual intervention and automatically correct any deviations.

Strong adaptability: able to handle wafers of different sizes, thicknesses, and shapes,

Ensure the flexibility of the production line.

Environmental adaptability: It can work in clean rooms and other high-precision environments,

Meets the strict standards of the semiconductor industry.

working principle:

Visual recognition and feedback: The aligner recognizes the position and direction of the wafer through its built-in camera or sensor,

And adjust through the control system to ensure precise alignment of the wafer during transportation or loading/unloading processes.

Precise control: Through stepper motors or other precision drive systems,

Adjust the position and angle of the wafer to ensure that there are no alignment errors in the subsequent processing technology.

Automatic correction: If any slight deviation is found during the wafer transfer process,

The system can automatically perform calibration to ensure high precision in continuous processing.

Size and load capacity:

The wafer aligner of this model is designed to accommodate wafers of different sizes

(such as 200mm, 300mm, etc.), and capable of handling various wafer boxes or carriers.

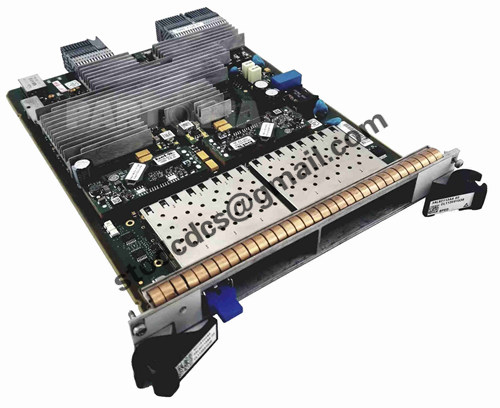

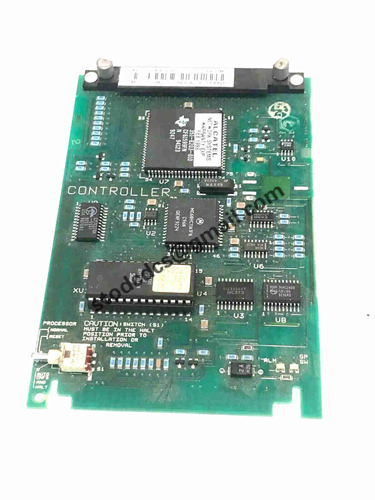

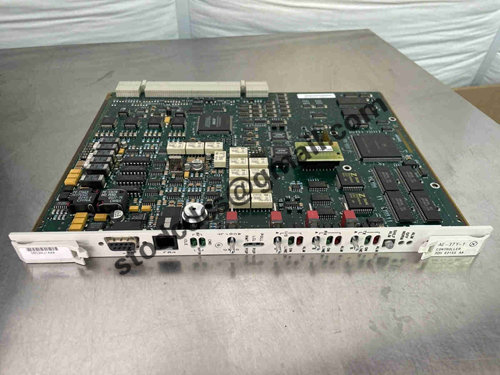

Product details picture:

More related products:

MOTOROLA MVME761-001 automation control module

Motorola RSG2PMC RSG2PMCF-NK2 Controlmodule

ZYGO ZMI-2002 8020-0211 Multi-axis interferometer