Details

Brooks 799-550205-001 Transfer Robot

Product manual:

The Brooks 799-550205-001 transfer robot is an automated transfer equipment designed specifically for the semiconductor and high-tech manufacturing industries,

Mainly used for efficient and precise material handling in clean room environments.

This type of robot is commonly used for wafer transfer, automatic loading and unloading, and precision operations,

Ensure seamless flow of products between different production stages.

Main features and specifications

Application areas:

Widely used in industries such as semiconductor, electronic manufacturing, and life sciences,

Especially in scenarios that require high precision and clean environments.

Commonly used in wafer transfer systems (such as transporting wafer boxes, boards, etc. in cleanrooms),

And support collaborative work with other automation devices.

Design and Construction:

Adopting modular design to facilitate system integration and expansion.

It has automatic positioning and navigation functions, and can perform precise positioning and path planning in complex environments.

Support various carriers for transporting items, such as crystal boxes, pallets, etc.

Performance characteristics:

High precision: With precise positioning and control capabilities, it ensures that items are not damaged during transportation.

Efficient automation: supports automated transportation and conveying, reduces manual intervention, and improves production line efficiency.

Strong adaptability: able to meet the high standard requirements of clean rooms, ensuring efficient and safe material transportation in a clean environment.

Intelligent control: By equipping advanced sensors, vision systems, and control algorithms, autonomous navigation and obstacle avoidance can be achieved.

Control system and interface:

Usually equipped with advanced control systems that support seamless integration with factory automation systems such as MES and SCADA.

Provide real-time monitoring, scheduling, and fault diagnosis functions to ensure stable equipment operation.

working principle:

Robots rely on precise navigation systems such as LiDAR and vision systems to automatically move in workshops or clean rooms.

When transferring items, the system will follow the preset path and task requirements,

Independently choose the optimal route, avoid obstacles, and accurately place items in designated locations.

Size and load capacity:

Suitable for handling items of various sizes and weights, and can support different load ranges according to configuration,

Usually applicable to standard semiconductor handling vehicles (such as wafer boxes, trays, etc.).

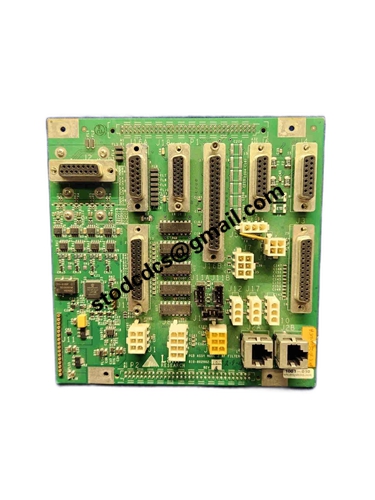

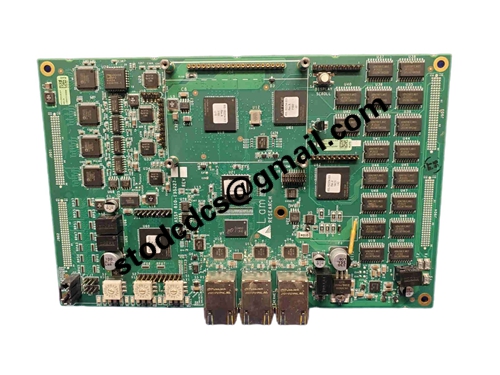

Product details picture:

More related products:

Helmholz 700-600-CAN01 Communication Module

MOTOROLA 188987-008R Analog module

MOTOROLA AET-3047 Industrial Performance control module