Details

Brooks 002-7391-07 Wafer Alignment Device

Product manual:

Brooks 002-7391-07 wafer aligner is a high-precision automation equipment provided by Brooks Automation,

Mainly used for wafer alignment and alignment tasks in wafer manufacturing, semiconductor processes, and other precision manufacturing processes.

It ensures the correct positioning and alignment of the wafer during wafer processing, thereby improving the accuracy and efficiency of the manufacturing process.

Main features and functions:

High precision alignment:

The Brooks 002-7391-07 wafer aligner utilizes advanced optical and mechanical technologies,

Capable of performing wafer alignment operations with extremely high precision.

Its accuracy can usually reach the micrometer level, ensuring precise positioning of the wafer during subsequent processing.

Automated operation:

This aligner supports fully automated operations and can automatically load, align, calibrate, and unload wafers.

Automated design reduces manual intervention, improves work efficiency and consistency.

Compatible with multiple wafer sizes:

This device is capable of processing wafers of different sizes,

Including common 200mm and 300mm wafers, suitable for various semiconductor processes and photovoltaic applications.

Real time monitoring and feedback:

The equipment has real-time monitoring function, which can monitor the wafer alignment status in real time.

Through a feedback mechanism, the system can adjust the position of the wafer to ensure accurate alignment.

High reliability and stability:

The Brooks 002-7391-07 wafer aligner design has high anti-interference ability and can operate stably in harsh environments.

Its durability makes it widely used in the semiconductor and photovoltaic industries, ensuring long-term continuous and stable operation.

Easy to integrate:

This aligner can be seamlessly integrated with other semiconductor production equipment, such as etching machines, lithography machines, thin film deposition machines, etc.

Its standardized interface supports rapid integration with existing automated production lines.

Simplified maintenance:

The aligner has a simple design and an easily accessible maintenance interface, making maintenance and repair processes more efficient and reducing downtime.

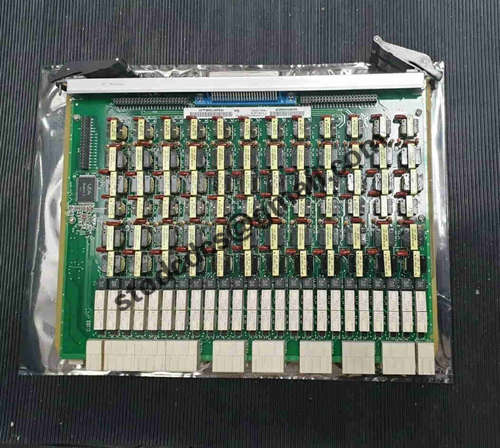

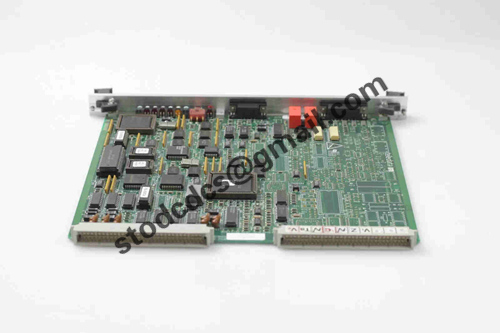

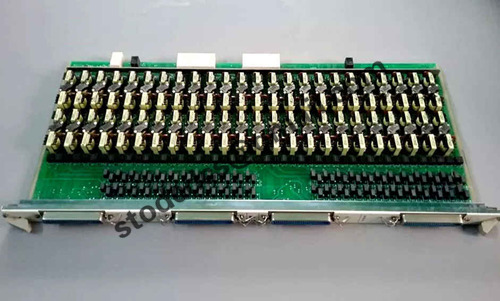

Product details picture:

More related products:

HIRSCHMANN MS3124-4 Communication Module

Helmholz 700-600-CAN01 Communication Module

MOTOROLA 188987-008R Analog module