Details

Brooks 001-0000-41 wafer index machine

Product manual:

Main features:

High precision positioning:

The Brooks 001-0000-41 wafer index provides high-precision rotation and positioning control, ensuring the accurate position of the wafer in each process step.

This precise positioning helps improve production consistency and reduce positional deviations of wafers during handling.

The precise positioning function allows for fine-tuning of the wafer to meet the needs of different equipment and processes.

Fast response time:

This indexer is capable of position adjustment with extremely short response times,

Suitable for high-speed and high-yield production environments.

It can quickly move wafers between multiple process steps, improving the efficiency of the entire production line.

Durability and cleanliness:

Design cleanroom standards that comply with semiconductor manufacturing, with materials that have low particle generation characteristics,

Can operate for a long time in a clean room environment without contaminating the wafer surface.

Has good durability, can withstand continuous operation, and adapts to the harsh environmental requirements of semiconductor manufacturing.

Compatibility and modular design:

The Brooks 001-0000-41 indexer features a modular design that is compatible with other Brooks or third-party automation devices.

Its design facilitates integration into wafer processing systems of different brands and models, enhancing the flexibility of the system.

The indexer supports multiple installation methods and can be flexibly configured in various devices, including cleaning, exposure, and etching equipment.

Real time feedback and monitoring:

Equipped with sensors and feedback systems, supporting real-time monitoring and position adjustment.

This feature allows for self diagnosis of the device during operation, reducing downtime caused by malfunctions.

Support communication interface with the upper control system, allowing operators to obtain real-time device status and perform maintenance in a timely manner.

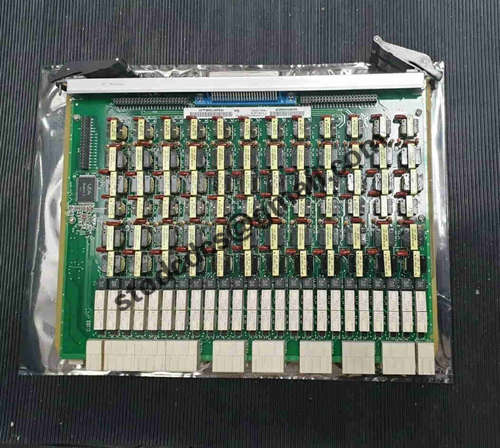

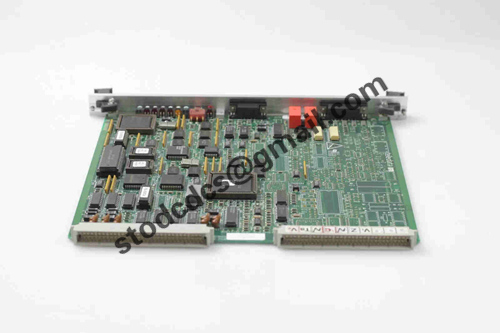

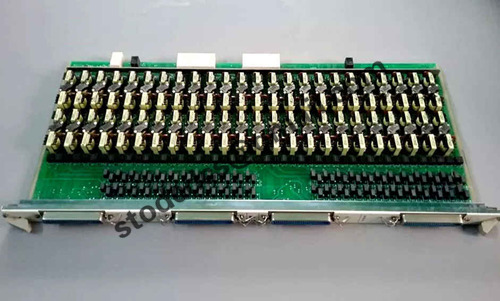

Product details picture:

More related products:

JETTER DIMA3-ES-16 Distributed Control System

Jetter JM-204-480-JC310-S1 servo drive

HIRSCHMANN ENT-10515-R AC Communication Card