Bently Nevada 3500/22M 146031-01 Transient Data Interface Module

Brand: Bently

Model:3500/22M 146031-01

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

Bently Nevada 3500/22M 146031-01 Transient Data Interface Module

Product manual:

Bently Nevada 3500/22M 146031-01 Transient Data Interface Module

It is a key module in the 3500 series monitoring system, specifically designed to capture and analyze transient data from equipment,

Changes such as vibration impact and instantaneous force can help detect potential equipment malfunctions in advance.

Main features:

Model: 3500/22M 146031-01

Function: This module is specifically designed to collect transient data and can capture real-time rapid vibrations or shock fluctuations of the device.

By sampling high-frequency data, it helps to identify abnormal changes in a short period of time in a timely manner.

Input/Output: Supports analog inputs from vibration sensors, accelerometers, etc., suitable for various industrial application scenarios.

Data transmission: Transient data is processed in real-time and transmitted through industrial communication protocols

(such as Modbus, Profibus, Ethernet) shared with other monitoring modules or control systems.

Compatible with other modules: Compatible with other monitoring modules in the Bently Nevada 3500 series,

It can be integrated with other data such as vibration monitoring, temperature monitoring, pressure monitoring, etc.

Application areas:

Equipment monitoring and fault diagnosis: used for equipment monitoring in industries such as power, oil and gas, mining, and manufacturing,

Especially suitable for equipment with frequent vibration and impact changes, such as turbines, pumps, compressors, etc.

Real time status monitoring: By monitoring transient data, sudden problems during device operation can be captured in real time, providing a basis for equipment maintenance and repair.

Fault prediction: Based on the changing patterns of transient data, it helps predict potential equipment failures and take preventive measures in advance.

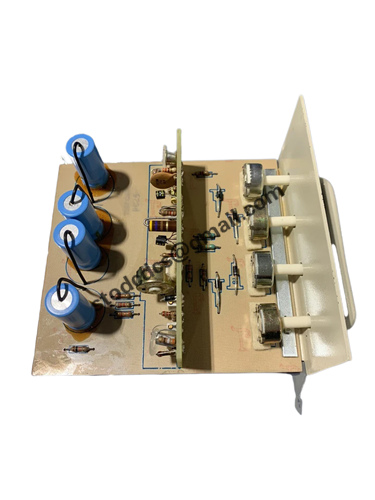

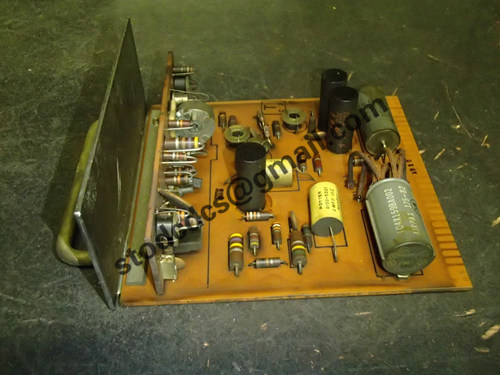

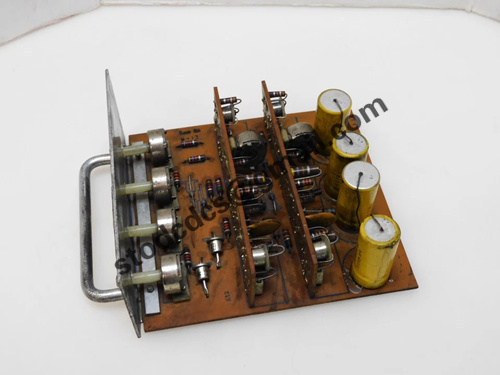

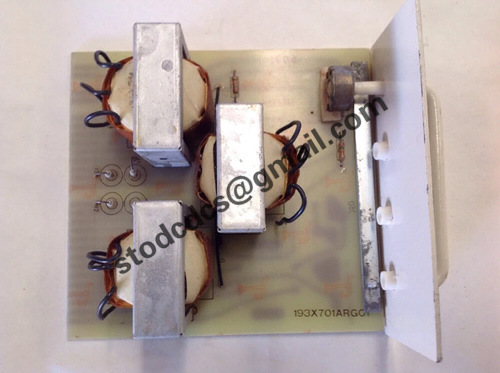

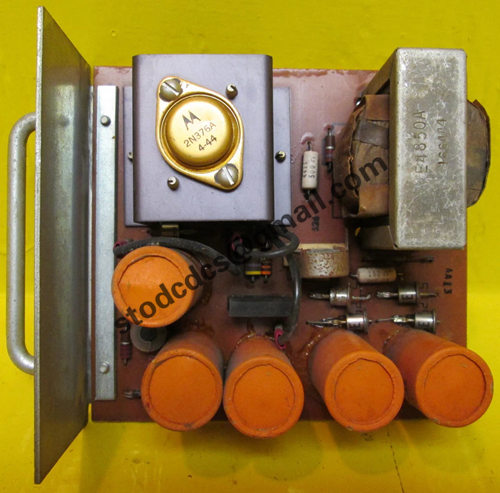

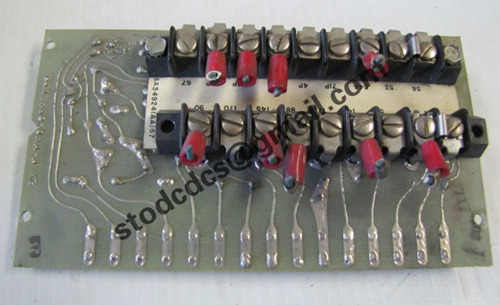

Product details picture:

More related products:

HIRSCHMANNENT-10515-RACCommunicationCard

6ES7313-1AD00-0AB0processormodule

HIRSCHMANNMS3124-4CommunicationModule