Brooks 002-1600-25 wafer transfer robot

Product details

Brooks 002-1600-25 is a robot specifically designed for wafer transfer in semiconductor manufacturing processes.

It is a high-precision, automated device produced by Brooks Automation,

Widely used in semiconductor, microelectronics, and other high-precision manufacturing fields,

Application areas:

Mainly used for automated transmission in semiconductor wafer production lines,

Ensure seamless integration of wafers from one process to another.

Used for high-precision wafer loading, unloading, and handling tasks in clean environments such as cleanrooms.

Design and Construction:

This model of robot has highly automated functions,

Capable of accurately moving wafers from one location to another.

The design takes into account extremely low vibration and pollution,

Suitable for the demanding requirements of cleanliness and accuracy in the semiconductor manufacturing process.

Equipped with high-precision control systems, typically including visual recognition and sensors,

To ensure that each transferred wafer is in the correct position.

Performance characteristics:

High speed automation: capable of quickly and effectively executing tasks, reducing production line downtime.

High precision: During wafer handling, the robot's accuracy can reach the micrometer level,

Ensure that the wafer is not damaged and remains in a stable position at all times.

Control system and interface:

Usually equipped with high-end control systems that support integration with factory automation systems,

Capable of coordinating with other production equipment.

Provide interfaces for connecting with factory information systems such as MES and SCADA,

In order to monitor device status, task scheduling, fault diagnosis, etc. in real-time.

working principle:

Robots transfer wafers from one area to another through robotic arms or similar motion devices.

The motion control system ensures precise execution of actions and avoids damaging the wafer.

Equipped with high-precision sensors and vision systems, capable of detecting the position of wafers

Realize intelligent dynamic adjustment of status and surrounding environment.

Size and load capacity:

This robot typically has a high load capacity and can handle multiple wafers simultaneously,

Or handle wafers of different sizes (such as 200mm and 300mm wafers).

The size and load capacity of the equipment depend on the specific model and configuration.

Efficient production: Through high automation and intelligence,

Reduce manual intervention and operational errors, improve production stability and efficiency.

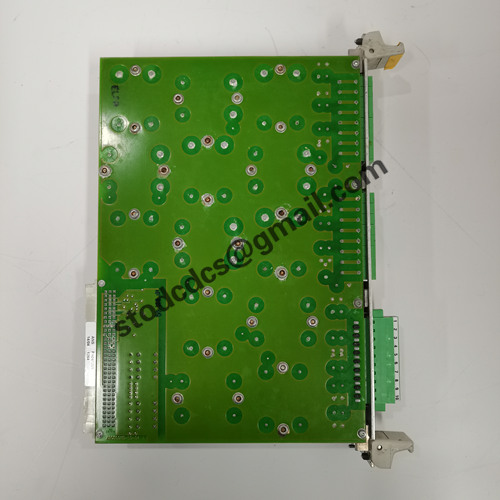

Related pictures:

More Industry News:

HIRSCHMANN ENT-10515-R AC Communication Card